| Important Information – Quick Reference | |

|

We strongly urge

that you read the information provided in pages referred hereunder which will help

in road safety and prevent

inconvenience

|

|

1

|

Warranty

Coverage...............................................................................................................................................

|

Refer WSIG* (P.g. 13)

|

|

2

|

Schedule Service

(Free/Paid)..........................................................................................................................

|

Refer WSIG* (P.g. 22)

|

|

3

|

Maintenance

Schedule........................................................................................................................................

|

Refer WSIG* (P.g. 24)

|

|

4

|

Lubricants and

Capacities..................................................................................................................................

|

Refer WSIG* (P.g. 26)

|

|

5

|

Location Of Vehicle Identification Number

(VIN)......................................................................................

|

Refer (P.g. 2-13)

|

|

6

|

Location Of Fuse Box And Fuse

Details........................................................................................................

|

Refer (P.g. 2-4)

|

|

7

|

Changing A Flat

Tyre.............................................................................................................................................

|

Refer (P.g. 2-8)

|

|

8

|

Understanding The Warning

Lamps.............................................................................................................

|

Refer (P.g. 4-3)

|

|

9

|

Use Of Seat Belts And Child

Restraint.......................................................................................................

|

Refer (P.g. 6-4 & 6-7)

|

|

10

|

Understanding The Airbag

Function..............................................................................................................

|

Refer (P.g. 7-1)

|

|

11

|

If Your Vehicle Is

Submerged...........................................................................................................................

|

Refer (P.g. 12-9)

|

|

12

|

Driving Through

Water.......................................................................................................................................

|

Refer (P.g. 12-10)

|

|

13

|

Opening And Closing The

Hood/Bonnet.....................................................................................................

|

Refer (P.g. 15-4)

|

|

14

|

Location Of Battery And Its

Maintenance..................................................................................................

|

Refer (P.g. 15-6/P.g. 15-17)

|

|

*Warranty & Service

Information Guide

|

1 INTRODUCTION AND SAFETY PRECAUTIONS

1.1 Introduction

Dear Customer,

Congratulations on purchasing Mahindra BOLERO. Your vehicle has been

designed to provide years of safe and dependable service,

as long as it is used and maintained in accordance with the instructions provided in this manual.

All persons who will use and/or maintain this vehicle must read,

understand and follow all warnings and instructions provided

in this manual. This Owner's Manual should be considered an integral part of the vehicle and should

remain with the vehicle.

However, nothing in this manual, and none of the safety devices installed in the vehicle, are a

substitute for careful operation

and common sense. Always make sure that your vehicle is in optimum working order, and take note of the

road and weather conditions

under which you are using your vehicle.

If you have any questions concerning the proper use or maintenance of

your vehicle, please call your Authorized Mahindra Dealer.

A list of dealers can be found in the Dealer Directory Supplement.

Alternatively you can contact Mahindra at,

| • | 1800-209-6006 (Toll free) |

| • | customercare@mahindra.com |

We extend our best wishes for safe and pleasurable motoring.

Sincerely,

MAHINDRA & MAHINDRA LTD

Servicing and Summary Data

| • | For all issues concerning the vehicle and for any need of spare parts, contact only the Authorised Mahindra Dealer network |

| • | We recommend you always use genuine Mahindra spare parts when performing repairs on the vehicle |

| • | We suggest that you record the vehicle data in the Warranty and Information Guide for future references |

1.1.1 Safety Symbols

Carefully read, understand and follow the safety symbols/

instructions given in this manual.

Legend of the Symbols

To emphasise information and procedures regarding safety, use,

maintenance, etc., the following symbols are used throughout

the manual:

DANGER indicates an

imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a

potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury and/or property damage.

NOTICE indicates important

information relevant to the vehicle, the vehicle's use or to sections of this manual to which

particular

attention must be paid for optimum use of the vehicle.

If you see this symbol, it indicates “no,” “do not,” “do not do

this,” or “never”.

For maximum vehicle

performance and safety considerations, always keep the following information in mind:

| • | The company does not take any responsibility for consequential damages / injuries resulting due to fitment of unauthorised aftermarket accessories and / or tapping / cutting wires in the wiring harness |

| • | When adding accessories, equipment, passengers and luggage to your vehicle, do not exceed the total weight capacity of the vehicle or of the front and rear axle. Consult Authorised Mahindra Dealer for specific weight information |

| • | Bull bars and nudge guards are not recommended |

| • | Accessories causing any change in vehicle specifications like wheel rims, bull bars, etc., may affect the performance of safety systems |

| • | Mobile communication systems such as two-way radios, telephones and theft alarms that are equipped with radio transmitters and installed in your vehicle should comply with the local regulations and should be installed only by your Authorised Mahindra Dealer |

2 GENERAL

2.1 Feature Matrix

In view of our policy of

continuously improving our products, we reserve the right to alter specification, designs or

features

without prior notice and without liability.

We recommend you to contact the

nearest Mahindra dealer for latest features applicable to your vehicle.

| Feature | B6 (O) | B6 | B4 | B2 |

| Technology | ||||

| Engine Immobilizer | Yes | Yes | Yes | Yes |

| Micro Hybrid System | Yes | Yes | Yes | Yes |

| Driver Information System | Yes | Yes | Yes | Yes |

| BT Audio with Mic in roof | Yes | — | — | — |

| Mechless Audio | Yes | Yes | — | — |

| Passenger Occupant Detection System (PODS) | Yes | Yes | Yes | — |

| Tiretronics | Yes | Yes | Yes | Yes |

| Comfort | ||||

| AC | Yes | Yes | Yes | — |

| Heater | Yes | Yes | Yes | — |

| Convenience | ||||

| Power Windows | All Four | All Four | — | — |

| Central locking | Yes | Yes | — | — |

| Keyless entry | Yes | Yes | — | — |

| Rear wash & wipe | Yes | — | — | — |

2.2 Dimensions

2.2.1 Front View

2.2.2 Rear View

2.2.3 Side View

| DIMENSION & WEIGHTS | mm |

|---|---|

| Wheel Base | 2680 mm |

| Overall Length | 3995 mm |

| Overall Width | 1745 mm |

| Overall Height | 1880 mm |

| Track Width (Front) | 1443 mm |

| Track Width (Rear) | 1346 mm |

2.3 Bulb Specification

| Lamp Bulb | Wattage | CAP Type | No. of Bulbs per Vehicle |

|---|---|---|---|

| Head Lamps | 12V 60/55W | H4-P43T | 2 |

| Front Turn Signal Lamp | 12V 21W (Amber) | BAU15D | 2 |

| Front Parking Lamps | 12V 5W | W5W | 2 |

| Side Turn Signal Lamps (Fender) | 12V 5W | W5W | 2 |

| High Mount Stop Lamp (Tail Door Type 1) | 12V 21W | BAS15D | 1 |

| Brake Lamp/Tail Lamp | 12V 21W/5W | BAS15D | 2 |

| Rear Turn Signal Lamp | 12V 21W | BAS15D | 2 |

| Reversing Lamp | 12V 21W | BAS15D | 2 |

| Rear License Plate Lamp | 12V 5W | W5W | 2 |

| Interior Courtesy Lamp | 12V 10W | C10W | 1 |

2.4 Fuses & Relays

2.4.1 Fuse and Relay - Engine

Compartment

Location - LHS of the engine

compartment, next to the battery

|

Fuse

No

|

Fuse

Rating

|

Circuit

|

|---|---|---|

|

F1

|

60A

|

BATTERY MAIN

|

|

F2

|

60A

|

GLOW PLUG

|

|

F3

|

60A

|

STARTER SOLENOID

|

|

F4

|

60A

|

MBFM +2

|

|

F5

|

— | — |

|

F6

|

60A

|

ELECTRIC FAN

|

|

F7

|

30A

|

EMS ECU

|

|

F8

|

40A

|

ABS SUPPLY

|

|

F9

|

30A

|

BLOWER MOTOR

|

|

F10

|

30A

|

ABS

|

|

F11

|

15A

|

H/L HIGH

|

|

F12

|

15A

|

H/L LOW

|

|

F13

|

15A

|

FOG LAMP

|

|

F14

|

30A

|

FEED PUMP

|

|

F15 to F17

|

— | — |

|

F18

|

5A

|

BMS

|

|

F19

|

5A

|

ECU B+

|

|

F20

|

15A

|

SCR*

|

|

F21

|

10A

|

Horn

|

|

F22

|

10A

|

*1 & +1

|

|

F23

|

5A

|

BFP

|

|

F24

|

15A

|

*2

|

|

F25

|

10A

|

ECU K-1**

|

|

F26

|

10A

|

ECU K-3

|

|

F27

|

— | — |

|

F28

|

10A

|

WATER PUMP

|

|

F29

|

10A

|

HFM SENSOR

|

|

F30

|

15A

|

*3

|

|

F31

|

10A

|

*4 & +1

|

|

F32

|

10A

|

SPARE

|

|

F33

|

10A

|

SPARE

|

|

F34

|

15A

|

SPARE

|

|

F35

|

15A

|

SPARE

|

|

F36

|

30A

|

SPARE

|

|

F37

|

— | — |

|

F38

|

— | — |

|

Relay

No

|

Circuit

|

|---|---|

|

R1

|

|

|

R2

|

COOLING FAN HI

|

|

R3

|

COOLING FAN LOW

|

|

R4

|

AC BLOWER RELAY

|

|

R5

|

STARTER SOLENOID RELAY

|

|

R6

|

GLOW PLUG RELAY

|

|

R7

|

HORN RELAY

|

|

R8

|

FOG LAMP / THERMO AMP RELAY (+3)

|

|

R9

|

H/L HIGH RELAY

|

|

R10

|

H/L LOW RELAY

|

|

R11

|

SCR*/BFP RELAY**

|

|

R12

|

AC COMP RELAY (+1)

|

|

R13

|

FUEL PUMP REALY

|

|

R14

|

ECU MAIN REALY

|

Battery Mounted Fuse Box

|

Fuse

Rating

|

Circuit

|

|---|---|

|

125 A

|

Alternator fuse/Charging fuse/Power ckt

|

|

80A

|

Fuse box bus bar

|

2.4.2 Fuse and Relay -

Passenger Compartment

|

|

Location - On the

driver side of the instrument panel

|

|

Fuse

Rating

|

Circuit

|

|---|---|

|

10A

|

AC Comp.

|

|

15A

|

Heater

|

|

10A

|

Turn/Rev.

|

|

10A

|

Wiper Washer Fr

|

|

10A/5A

|

Wiper Washer RR/Demister*

|

|

10A

|

Air bag IGN

|

|

5A

|

ABS Tell tale

|

|

5A

|

ABS Ign

|

|

15A

|

Cluster

|

|

15A

|

IMMOB.

|

|

15A

|

Flasher Control

|

|

5A

|

Diag./Immo/ITC

|

|

10A

|

Audio/Cluster

|

|

10A

|

Park Lamp

|

|

5A

|

Display Module

|

|

10A

|

Roof Lamp

|

|

20A

|

MBFM-1

|

|

20A

|

MBFM-2

|

|

20A

|

MBFM-3

|

|

30A

|

P/W Switch

|

|

10A

|

Audio

|

|

Relay

Rating

|

Circuit

|

|---|---|

|

40A

|

Blower Controller Relay

|

|

-

|

Wiper Intermittant Controller

|

2.5 Flat Tire

Reduce your speed gradually, keeping a straight line. Move cautiously off

the road to a safe place well away from traffic.

Park on a level spot with firm ground. Stop the engine and turn ON your hazard warning flashers.

Firmly apply the parking brake. Have everyone come out of the vehicle on

the side away from traffic..

Never stop your vehicle in a

traffic lane to change a tire. You could be hit by an oncoming vehicle. Keep driving until you

reach a safe location.

Lifting a vehicle to change a tire or perform maintenance is very

dangerous if you do not have the requisite tools, safety

equipment and training. The jack provided along with the vehicle is to be used only for changing a spare

tire. It is never

to be used to perform any other maintenance or repair on the vehicle.

Never place any part of your body

under any portion of the vehicle when it is supported only by the jack. You could be crushed

by the vehicle if it falls off a jack. Keep by-standers away from the vehicle.

Find level, solid ground that is clear of oncoming traffic. If you cannot

find a safe place to stop, it is better to drive

on a flat tire and damage the rim than it is to risk being hit by oncoming traffic.

After changing a flat tire, never store the tire or other equipment in

the passenger compartment of the vehicle. This loose

equipment could strike an occupant in the event of a sudden stop or collision. Store all of these items

in the proper place.

The following sections outline the

procedure for changing a flat tire;

2.5.1 Jack/Wheel Spanner/Warning

Triangle

The jack along with the wheel spanner and other tools are located on

the floor between the third row seats near to the back

door as shown in figure. Rotate the two securing knobs and lift the lid to access the jack. The jack

extension and warning

triangle are placed beneath the front passenger seat. Slide the seat backwards, pull open the velcro

and access the warning

triangle or jack handle.

2.5.2 Spare Wheel Removal

Spare wheel is mounted on the tail gate at the rear end of the

vehicle. It is held in place by mountings nuts covered by a

spare wheel cover (if equipped).

|

A

|

Spare Wheel

|

B

|

Spare Wheel Cap

|

|

C

|

Spare Wheel Cover

|

D

|

Mounting Nuts

|

| • | Remove the spare wheel cover (if equipped)by pulling at its edges as shown in figure |

| • | Remove the mounting nuts holding the spare wheel cover and spare wheel |

| • | Dismount the spare wheel |

Do not try to pry off the wheel

cover by hand alone. Take due care in handling the wheel cover to avoid unexpected personal

injury.

2.5.3 Wheel Nut Loosening

Always loosen the wheel nuts before raising the vehicle. Turn the

wheel nuts counter clockwise to loosen. To get maximum leverage,

fit the spanner to the nut so that the handle is on the left side. Grab the spanner near the end of

the handle and push down

on the handle. Be careful that the spanner does not slip off the nut. Do not remove the nuts, but

loosen them by one or two

turns.

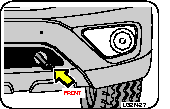

2.6 Jack Points

Front jack up point - below

chassis side long member just behind the front wheels.

Rear jack up point -under rear

axle.

|

A

|

Rear Jacking Points

|

B

|

Front Jacking Points

|

2.6.1 Jacking

Block the wheel diagonally opposite the flat tire to keep the vehicle

from rolling when it is jacked up. When blocking the

wheel, place a wheel block in front of one of the front wheels or behind one of the rear wheels.

Position the jack at the correct jacking point. Make sure the jack is

positioned on a level and solid place. Ensure no one

is in the vehicle.

To raise the vehicle, insert the jack handle end along with the

extension into the jack and turn it clockwise with the jack

handle. As the jack touches the vehicle and begins to lift, check that it is properly positioned.

Raise it high enough so

that the spare tire can be installed. Remember you will need more ground clearance when putting on the

spare tire than when

removing the flat tire.

|

A

|

Flat Tire

|

B

|

Chock Blocks

|

Block the wheel diagonally opposite the flat tire to keep the vehicle

from rolling when it is jacked up. When blocking the

wheel, place a wheel block in front of one of the front wheels or behind one of the rear wheels.

Make sure to set the jack

properly in the jacking point. Raising the vehicle with improperly positioned jack will damage

the

underbody of vehicle or may allow the vehicle to fall off the jack and cause personal

injury.

| • | Use the jack only for lifting your vehicle during wheel changing |

| • | Do not raise the jack with someone in the vehicle. |

| • | When raising the vehicle, do not place any objects on top of or underneath the jack. |

| • | Raise the vehicle only high enough to remove and change the wheel. |

| • | Follow jacking instructions |

| • | Do not start or run the engine while your vehicle is supported by the jack. |

Never get under the vehicle

when the vehicle is supported by the jack alone.

Remove the wheel nuts. Lift the flat tire straight off and place it

aside. Roll the spare wheel into position and align the

holes in the wheel with the bolts. Lift up the wheel and get at least the top bolt started through its

hole. Wiggle the wheel

and press it back over the other bolts.

Re-install the wheel nuts with the tapered end inward and tighten by

hand. Press the wheel inward and tighten the wheel nuts

further.

Never use oil or grease on the

bolts or nuts. Doing so may lead to over tightening the nuts, wheel nut spanner slip, damage

the bolts and also may cause personal injuries. Also, nuts may loosen and the wheels may fall

off, which could cause a serious

accident. If there is oil or grease on any bolt or nut, clean before installing wheel

nuts.

Lower the vehicle completely and tighten the diagonally opposite wheel

nuts using the wheel nut spanner. Turn the jack handle

extension counter clockwise using the jack handle to lower the vehicle, making sure the handle remains

firmly fitted onto

the jack handle extension. Make sure the wheel spanner is securely engaged over the nut. Tighten each

nut a little at a time

in the diagonally opposite order. Repeat the process until all the nuts are tight. Do not use other

tools or any additional

leverage other than your hands, such as a hammer, pipe or your foot.

Improperly or loosely tightened

wheel nuts are dangerous. The wheel could wobble or come off. This could result in loss of

vehicle control and cause a serious accident. Always make sure all the wheel nuts are

properly/securely tightened to the specified

torque.

When lowering the vehicle, make

sure all portions of your body are clear off the vehicle as it is lowered to the ground. Have

the wheel nuts tightened with the torque spanner to the required torque, as soon as possible

after changing wheels.

If you have rotated , repaired

, changed your tires or changed the wheel rims, check the wheel nuts are still tight (to the

reqd. torque) after driving about 1000 Kms.

Put the wheel cover into position aligning the nozzle on the wheel to

the nozzle clearance on the wheel cover. Tap it firmly

on the sides with your hand to snap it into place.

Check the air pressure of the replaced tire. If the pressure is lower

than recommended, drive slowly to the nearest service

station and inflate to the correct pressure. If it is too high, adjust it until it is correct. Always

reinstall the valve

cap after checking or adjusting tire pressure. If the cap is not replaced, dirt and moisture could get

into the valve core

and cause air leakage. If you lose a valve cap, buy another and install it as soon as possible.

2.6.2 Restore all the Tools, Jack

and Flat Tire Securely

Mount the flat tire to the rear door of the vehicle. Firmly tighten

the securing nut and put the spare wheel cover back. Replace

the tools (jack, wheel spanner, etc.,) in their storage location.

Double check to ensure the flat tire along with the wheel cover is

securely mounted on the tail gate.

It is recommended to fix the

flat tire at the nearest tire shop and swap the spare wheel back. The wheel balance and

alignment

differ from wheel to wheel. This may lead to steering and braking issues.

2.7 Vehicle Identification Number (VIN):

Vehicle Identification Number (VIN) is the legal identity of your

vehicle. The vehicle identification number is stamped on

the VIN plate fixed on the fire wall above the battery in the left side of the engine compartment.

2.8 Engine Number

The engine number is punched on the left hand side of the engine front

end near the fuel pump mounting.

2.9 Chassis Number

The chassis number is punched on the right side chassis side member below

the front fender. It is also stamped on the VIN

plate located on the left side of the engine compartment. This is shows only the identification of

location for the VIN Plate

stamped.

2.10 Technical Specifications

|

Technical

Specifications

|

|||

|---|---|---|---|

|

ENGINE

|

mHawk

|

||

|

Displacement/Cubic Capacity

|

1493 cc

|

||

|

Compression Ratio

|

16.5:1

|

||

|

Max. Net Power

|

55.9 kW @ 3600 RPM

|

||

|

Max. Net Torque

|

210 Nm @ 1600 – 2200 RPM

|

||

|

TRANSMISSION

|

|||

|

Type

|

5 Speed Manual - Synchromesh in all Forward Gears

|

||

|

No. of Gears

|

5 Forward, 1 Reverse

|

||

|

GEAR

RATIOS

|

|||

|

I

|

3.96:1

|

||

|

II

|

2.21:1

|

||

|

II

|

1.42:1

|

||

|

IV

|

1.00:1

|

||

|

V

|

0.79:1

|

||

|

Reverse

|

3.56:1

|

||

|

WHEELS &

TIRES

|

|||

|

Rim

|

6.0J x 15"

|

||

|

Tires

|

215/75 R15

|

||

|

No. of wheels

|

5 (Inclusive of Spare Wheel)

|

||

|

STEERING

|

|||

|

Type

|

Power Assisted, Rack & Pinion

|

||

|

Turning Circle Diameter

|

11.6 m

|

||

|

SUSPENSION

|

|||

|

Front

|

Independent Front with Coil Spring

|

||

|

Rear

|

Rigid Semi-elliptic Leaf Spring

|

||

|

Anti Roll Bar

|

Front — Torsion Type, Rear — NA

|

||

|

Shock Absorbers

|

Hydraulic, Double Acting, Telescopic

|

||

|

BRAKES

|

|||

|

Type

|

Hydraulic with Vacuum assisted

|

||

|

Front

|

Disc

|

||

|

Rear

|

Drum

|

||

|

Parking Brake

|

Mechanical (hand operated) acting on rear wheel

|

||

|

FUEL

|

|||

|

Fuel Capacity

|

60 liters

|

||

|

ELECTRICAL

SYSTEM

|

|||

|

System Voltage

|

12V

|

||

|

Battery

|

65 Ah

|

||

3 VEHICLE OVERVIEW

3.1 Front Overview

| A | Bonnet |

| B | Windshield |

| C | Windshield Wiper |

| D | Windshield Washer Jet |

| E | Outside Rear View Mirror (ORVM) |

| F | Front Turn Signal Lamp |

| G | Head Lamp/Static Bending Lamp |

| H | Parking Lamp |

| I | Fog Lamp |

| J | Tow Hook |

3.2 Rear Overview

| A | Tail/Brake Lamp |

| B | Tail Door/Gate |

| C | Rear Wiper |

| D | Rear Windshield |

| E | Reversing Lamp |

| F | License Plate Lamp |

| G | Spare Wheel |

| H | Rear Foot Step |

| I | Rear Tow Hook |

| J | Rear Turn Signal Lamp |

| K | Reverse Parking Assist Sensor |

3.3 Instrument Panel Overview

| A | Side Vents | I | Horn pad/Driver Airbag |

| B | Passenger Airbag | J | Head Lamp Leveling Switch |

| C | Audio System* | K | Stop/Start Switch* |

| D | Centre Vents | L | Gear Shift Lever |

| E | Driver Information Display | M | Parking Brake |

| F | Hazard Warning Switch | N | Power Socket |

| G | Steering Wheel | O | AC Controls |

| H | Instrument Cluster | P | Glove Box |

| *-if equipped | |||

4 INSTRUMENT CLUSTER OVERVIEW

4.2 Warning Lamps Overview

| Sr. No. | Symbol | Warning Lamp/Tell Tale | Lamp Pre-check | Lamp Status after Engine ON | Action/Remarks |

|---|---|---|---|---|---|

| A |

|

Parking Lamp | Continuously ON | Indicates parking lamp is ON. | |

| B |

|

Battery Charging Warning Lamp | Continuously ON till Engine Starts | Continuously ON |

Indicates malfunction in charging system. Contact

Authorized Mahindra Dealer for assistance

|

| C |

|

Fog Lamp * | No |

Indicates Fog Lamp is ON

|

|

| D |

|

Immobilizer Lamp * (Ignition ON) | Yes | Continuously ON or blinking | Vehicle might have been immobilised, contact Authorized Mahindra Dealer for assistance |

|

|

Immobilizer Lamp * (Ignition OFF) | N/A | Blinking |

Slow

Blinking: Vehicle is armed with the remote

Fast

Blinking: Vehicle is disarmed with remote

|

|

| E |

|

Low Engine Oil Pressure Warning Lamp | Continuously ON till Engine Starts | Continuously ON |

Indicates engine oil pressure is low. Check oil

level and top-up or contact an Authorized Mahindra Dealer for assistance

|

| F |

|

Check Engine Lamp | For About 2 Seconds | Continuously ON or Blinking |

There is a potential malfunction in the engine

system, contact an Authorized Mahindra Dealer immediately

|

| G |

|

Parking Brake ON/Brake Fluid Low Warning Lamp/EBD malfunction | Yes | Continuously ON |

Either one of below conditions-

1) Park Brake might be engaged

2) Brake fluid level might be low

3) EBD Malfunction detected

Contact Authorized Mahindra Dealer immediately

for assistance if lamp is not turning OFF even after checking the above

conditions.

|

| H |

|

High Coolant Temperature Warning Lamp | Yes | Continuously ON or Blinking |

Continuously

ON: Normal

Blinking:Engine temperature very high (>108ºC). Contact

Authorized Mahindra Dealer for assistance

|

| I |

|

Head Lamp High Beam Indicator | Continuously ON |

Indicates Head lamp high beam is ON

|

|

| J |

|

Right Turn Indicators | Slow or Fast Blinking |

Indicates right turn lamp is blinking

Slow

Blinking: Normal operation

Fast

Blinking: One /more right turn lamp bulb has fused. Have the bulb

replaced

|

|

| K |

|

Low Fuel Warning Lamp | NO | Blinking | The fuel level in the fuel tank is low. Re-fuel immediately to avoid empty tank situation. If the lamp does not come ON or blink, contact Authorized Mahindra Dealer for assistance |

| L |

|

Left Turn Indicators | Slow or Fast Blinking |

Indicates left turn lamp is blinking

Slow

Blinking: Normal operation

Fast

Blinking: One /more left turn lamp bulb has fused. Have the bulb

replaced

|

|

| M |

|

Micro Hybrid-Stop/Start Lamp * | Continuously ON or Blinking |

Continuously

ON: Engine is in auto stop mode

Blinking: Micro Hybrid is about to stop the engine

|

|

| N |

|

Tiretronics Warning Lamp | Yes | Continuously ON or Blinking | Indicates low/high tyre pressure or possible malfunction in Tiretronics. Refer to Tiretronics section in WHEELS & TYRES chapter for further details. |

| O |

|

Water in Fuel Filter Warning Lamp | For about 2 seconds | Continuously ON | Indicates water in fuel filter. Drain the water from filter or contact an Authorized Mahindra Dealer for assistance |

| P |

|

Glow Plug Lamp | For about 2 seconds | Continuously ON | Indicates a malfunction in the starting system. Please contact Authorized Mahindra Dealer for assistance |

| Q |

|

OBD Check Lamp (MIL) | Continuously ON till Engine Starts | Continuously ON | There is a potential malfunction related to emission control system, contact an Authorized Mahindra Dealer immediately |

|

* if equipped / select models or variants only

|

|||||

4.3 Driver

Information System (DIS) Overview (if equipped)

| A | Airbag | G | Set Button |

| B | Seat Belt Warning Lamp | H | Mode Button |

| C | DEF Indicator Lamp | I | Driving Time (DT) / Average Fuel Efficiency (AFE) / Distance To Empty (DTE) |

| D | DPF Indicator Lamp | J | Door Ajar Warning Lamp |

| E | Time | K | ABS Warning Lamp |

| F | Gear Indicator |

5 EMISSION CONTROL SYSTEM

The emission control system is a highly effective system which controls

exhaust emissions from the engine and crucial for

meeting emission norms specified by law.

Your vehicle is equipped with the following emission control systems for

meeting BS VI emission norms.

| 1. | Diesel Oxidation Catalyst (DOC) |

| 2. | Selective Catalytic Reduction(SCR) |

| 3. | Diesel Particulate Filter (DPF) |

In order to assure the proper function of the emission control systems, it

is recommended that you have your vehicle inspected

and maintained by an authorized Mahindra dealer in accordance with the maintenance schedule in this manual.

It is also extremely important to use the correct grade of fuel, Confirming

to IS 1460; 2017 BS VI Specification.

5.1 Diesel Oxidation Catalyst (DOC)

A diesel oxidation catalyst (DOC) is an after treatment component that is

designed to convert carbon monoxide (CO) and hydrocarbons

(HC) into carbon dioxide (CO2) and water (H2O).

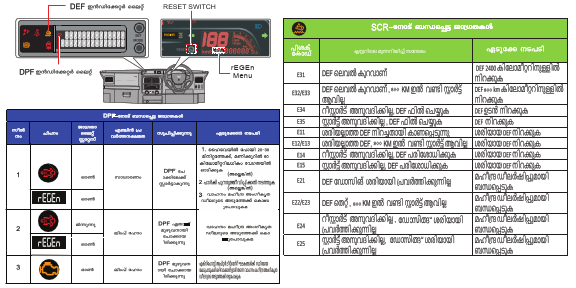

5.2 Selective Catalytic Reduction(SCR)

Selective Catalytic Reduction (SCR) is an advanced active emission

control technology system that injects a liquid-reducing

agent through a special catalyst into the exhaust stream of a diesel engine. The reductant is called as

Diesel Exhaust Fluid

(DEF). The DEF sets off a chemical reaction that converts nitrogen oxides into nitrogen and water which

is then expelled through

the vehicle tailpipe.

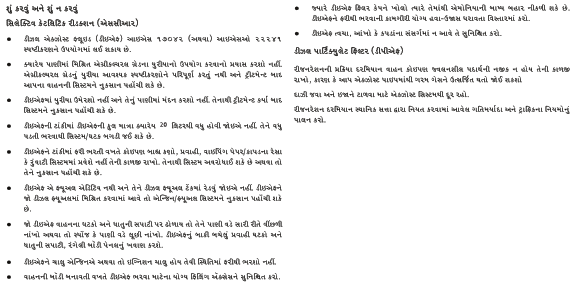

5.2.1 Diesel Exhaust Fluid (DEF)

MaxiCLEAN

To enable SCR system work efficiently and to ensure emission

compliance, It is recommended to use MaxiCLEAN DEF meeting IS

17042 (or) ISO 22241 specification.

Refilling DEF is part of regular maintenance service. DEF consumption

is highly dependent on driving conditions/pattern. It

may be necessary to refill DEF reservoir in-between the scheduled service, You need to monitor DEF

Indicator Tell Tale and

symbols/text messages displayed on infotainment screen / Cluster.

MaxiCLEAN DEF is available at all the authorized Mahindra dealers in

variable packs. Individual DEF Packs may have specific

filler neck, for filling DEF in the vehicle. While refilling DEF, Ensure no spillage on the body of

self and vehicle to avoid

any stains or inconvenience.

It is unlawful to tamper with

or remove any component of the after treatment system. It is strongly recommended not to use

DEF which is not meeting above specification. Further, this may lead to emission non-compliance

and warranty will be void.

| • | Use Genuine DEF MaxiCLEAN always. |

| • | Incase of non-availability of above Diesel Exhaust Fluid (DEF) complying to IS 17042 (or) ISO 22241 specification can be used. |

| • | Never attempt to use agricultural grade urea mixed with water. Agricultural grade urea does not meet the necessary specifications and the after treatment system of your vehicle may be damaged. |

| • | Total DEF quantity inside the DEF Tank should never be more than 20 liters. Overfilling may result in system/component failure. |

| • | DEF quality and purity can be ensured only if it is stored properly. Hence ensure the storage of DEF in cool, dry place between storage. |

| • | Do not add urea to DEF and do not dilute with water. This may cause after treatment system damage. |

| • | While refilling DEF inside tank, be careful not to allow any foreign particles, liquids, wiping paper/clothing fibers or lint to get inside the system. These may clog or damage the system. |

| • | If DEF is spilled over vehicle components and metal surfaces, rinse with water or wipe off with sponge and water. DEF residues will corrode the components and metal surfaces, painted body panels. |

| • | DEF is not a fuel additive and must not be added to the diesel fuel tank. If DEF is mixed with the diesel fuel, engine/fuel system could get damaged. |

| • | In such a case , do not start the engine and immediately contact nearest Mahindra Authorised Dealer for assistance. |

5.2.2 Contamination/ Incorrect DEF

In the event that incorrect or contaminated fluid is filled inside DEF

Tank, contact an authorized M&M dealer to determine

the appropriate repair direction.

5.2.3 Handling of DEF

| • | Ensure that DEF does not come into contact with skin, eyes, or clothing |

| • | Keep DEF out of the reach of children |

| • | In case if any part of the body is in contact with DEF, clean affected area immediately with plenty of water |

| • | If DEF contacted with eyes, flush with plenty of water immediately and seek medical help. |

| • | If DEF is swallowed, rinse mouth immediately with plenty of water, drink plenty of water immediately and seek medical help. |

| • | Don’t store DEF refill containers inside the vehicle. Ammonia vapors may escape from container which have a pungent odor and are particularly irritating for skin, mucous membranes and eyes. Inhaling ammonia vapors may cause burning eyes, nose and throat, as well as cough and watering eyes. |

| • | When opening the DEF filler cap, ammonia vapors may escape. Refill DEF in a well ventilated area only. |

| • | If Diesel Exhaust Fluid is spilled on metal surfaces rinse and clean immediately with water. Failure to do so may leave permanent corrosive stains on the metal surfaces which cannot be removed. |

5.2.4 DEF Operating Condition

DEF will freeze at -11°C (12.2°F). This is natural phenomenon. The DEF

system in the vehicle is designed considering this

and does not require any external heating or additives to avoid freezing.

The Diesel Exhaust Fluid (DEF)

system purges to prevent damage from freezing. Do NOT disconnect battery power within 20 minutes

of switching the ignition key off. Failure to comply may result in vehicle or property

damage.

5.2.5 Refilling DEF

DEF Filler Neck is located on the left side of the vehicle.

Following below steps to refill the DEF:

| 1. | Park the vehicle on level ground and switch OFF the ignition. |

| 2. | DEF filler flap need to open by lever provided behind

LH side Side facing seat. LH Side seat to be unfold for accessing DEF

filler flap.

|

| 3. | Turn the DEF filler cap by rotating it anti-clockwise and remove. |

| 4. | Fill DEF from the Container Pack. Each container pack has unique mouth and filling provision. Ensure utilizing the same and avoid spillage. Example. 10 Lit. Pack provided with filler tube. |

| 5. | Fill DEF as required. Maximum Storage capacity 20 litre. Minimum filling 5.0 liter. |

| 6. | Rinse with water or use sponge wetted with water to clean the components/surfaces in case of DEF spills over. |

| 7. | Put the DEF filler cap back in its place and tighten in the clock wise direction, then close the DEF filler flap. |

| 8. | Switch the ignition ON |

| 9. | Verify that there is no warning regarding DEF low level. If DEF Level Low warning is still appearing, Check enough quantity filled, If still problem persist Contact nearest Authorized Mahindra Dealer immediately. |

| 10. | DEF is being monitored through iSmart tool during regular service at dealership and quantity will be filled accordingly. |

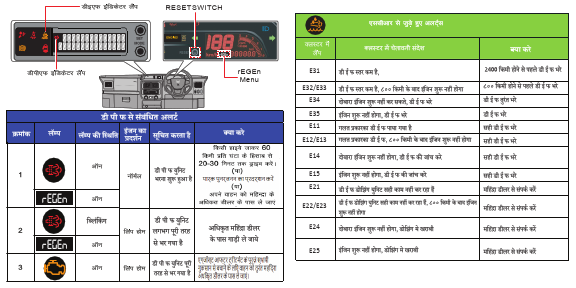

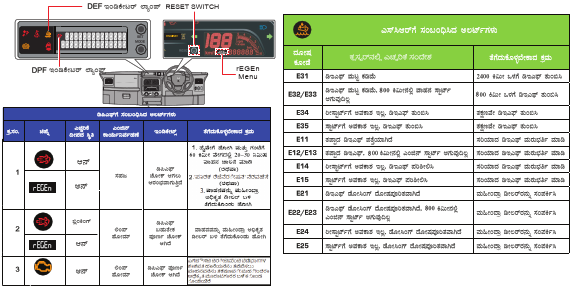

5.3 Diesel Particulate Filter (DPF)

The Diesel particulate filter (DPF) is an integral part of the vehicle

exhaust gas emission reduction systems and it removes

the soot from (Particulate matter) the exhaust gas. Unlike a disposable air filter, the DPF is

regenerative filter. Regeneration

is triggered automatically according to the driving conditions which burns of the accumulated

particles/soot. In other words,

the active burning by engine control system and high exhaust gas temperature caused by normal/high

driving condition burns

and removes the accumulated soot. The process is called as DPF Active

Regeneration.

However, if the vehicle continues to be driven at either of the

following conditions the accumulated soot may not be automatically

removed because of low exhaust gas temperature.

| 1. | Heavy traffic driving conditions, especially in city |

| 2. | Frequent short trips |

| 3. | Low speed for a long time |

When more than a certain amount of soot deposited, the DPF lamp

illuminates.

If the DPF lamp turns ON or

blinking while driving the vehicle and the message “REGEN

REQUIRED” appears in DIS unit, it indicates DPF regeneration has not occurred successfully. At

this moment, we suggest DPF regeneration

must be done through a specific methodology.

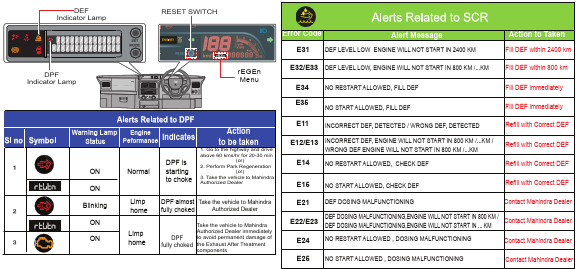

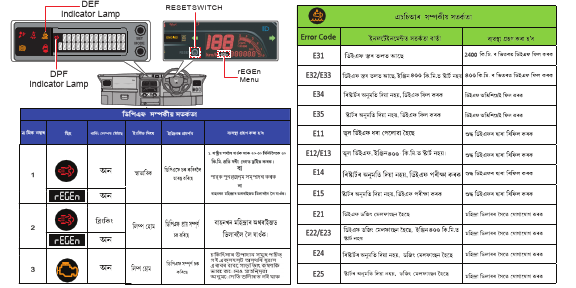

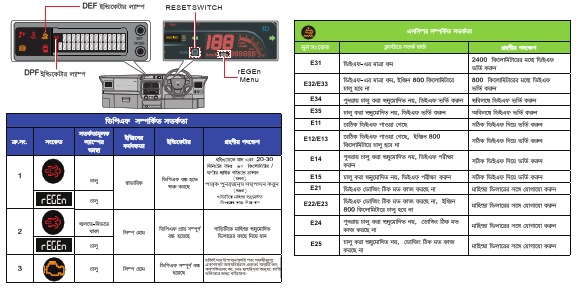

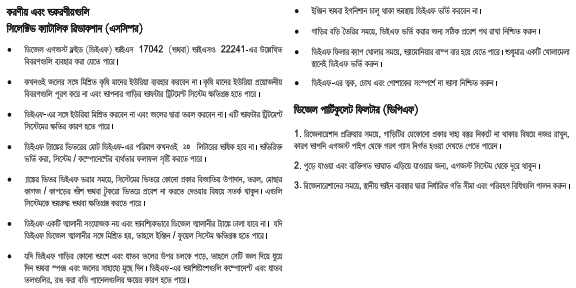

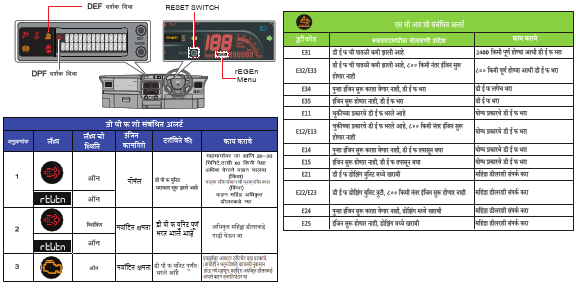

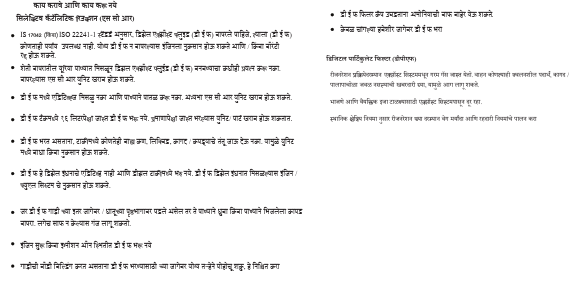

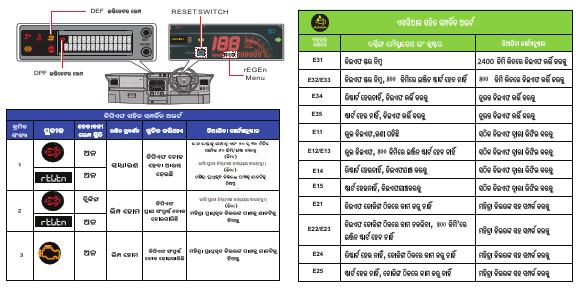

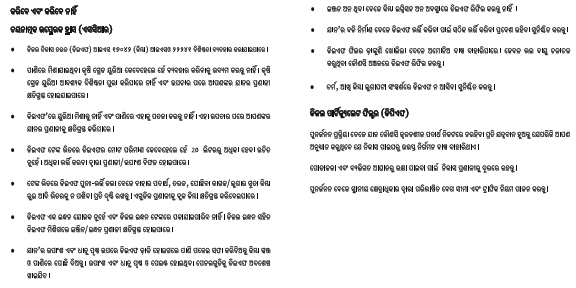

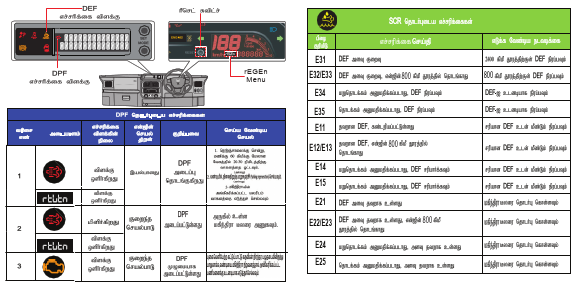

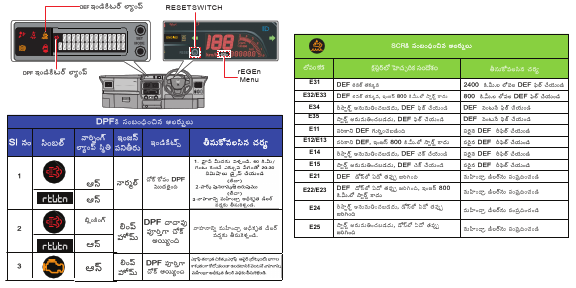

Instrument Cluster Telltale & DIS

Alerts —

The same is as mentioned

below:

1. Take vehicle to highway and drive for 20–30 mins @ speeds above

60 kms/hr until the lamp turns OFF (or)

2. Park Regeneration to be done as per the below procedure

Park regeneration is only possible when the rEGEn menu is available in the instrument cluster

| • | Park the vehicle safely in a well ventilated levelled open space and free of any flammable material |

| • | Shift the gear lever to Neutral with the engine running and apply the parking brake |

| • | Press RESET switch & toggle until rEGEn displayed in Cluster |

| • | Press and hold the RESET switch until “REGEN REQUESTED” is displayed in DIS |

| • | Then “REGEN STARTED” message will appear in DIS and engine idle speed will increase indicating regeneration has started if all conditions are met. |

| • | Park Regeneration can take up to 30 minutes to complete. Once completed the “REGEN COMPLETED” message in the DIS and DPF Lamp in cluster will turn OFF. |

Incase of an emergency where in the Park Regeneration process needs to be

interrpted/aborted, press the Clutch/Brake/Accelerator

pedal or turn off the ignition switch. Park regeneration can be resumed from the beginning if the DPF

tell-tale is ON/Blinking.

Park Regeneration process may not start if certain conditions are not

satisfied and “REGEN NOT STARTED” message will appear in

DIS

Park Regeneration process may get aborted in between if certain

conditions are not met and “REGEN ABORTED” message will

appear in DIS

Park Regeneration process may not start if CHECK ENGINE LAMP or OBD

are ON in the cluster. Take vehicle to Mahindra Authorised

dealer for assistance.

When Park Regeneration is happening do not press the Accelerator,

Brake or Clutch pedals as this will cancel the regeneration

process.

When Park regeneration is happening switching off the ignition will

cancel the regeneration process. The park regeneration

process may not start if requested when the engine is switched ON again. Take the vehicle to highway

and drive for 20-30 minutes

at speeds above 60 km/hr until DPF warning lamp turns OFF.

Diesel Fuel

It is recommended to use the regulated automotive diesel fuel

confirming to IS 1460: 2017 spec only.

If the diesel fuel with high sulfur content (more than 10 PPM) and

unspecified additives are used, it can cause the DPF system

damage and emission warranty issues.

| • | During the regeneration process, take care the vehicle is not near any flammable materials as you may observe hot emission gases from exhaust pipe. |

| • | In order to avoid burns & personal injury, stay yourself away from exhaust system. |

| • | Follow speed limits & traffic regulations as defined by local jurisdiction while doing forced regeneration. |

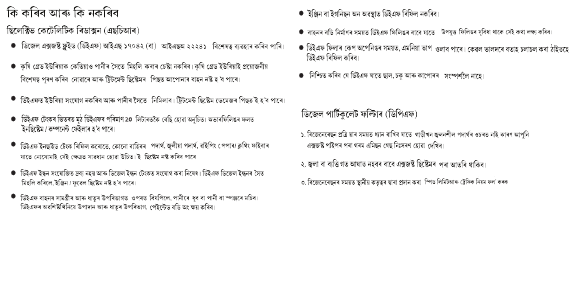

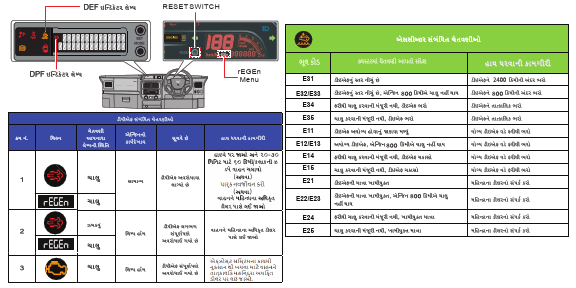

5.4 Digital Information System (DIS)

Do's & Don’ts

Selective Catalytic

Reduction(SCR)

| • | Diesel Exhaust Fluid (DEF) IS 17042 (or) ISO 22241 specification can be used. |

| • | Never attempt to create Diesel Exhaust Fluid (DEF) by mixing agricultural grade urea with water. Agricultural grade urea does not meet the necessary specifications required and the after treatment system may be damaged. |

| • | Do not add additives to DEF and do not dilute with water. Otherwise, the exhaust gas after treatment system could be damaged |

| • | Total DEF quantity inside the DEF Tank should never be more than 20 liters. Overfilling may result in system/component failure. |

| • | While refilling DEF inside tank, be careful not to allow any foreign particles, liquids, wiping paper/clothing fibers or lint to get inside the system. These may clog or damage the system. |

| • | DEF is not a fuel additive and must not be added to the diesel fuel tank. If DEF is mixed with the diesel fuel, engine/fuel system could get damaged |

| • | If DEF is spilled over vehicle components and metal surfaces, rinse with water or use sponge wetted with water. DEF residues will corrode the components and metal surfaces, painted body panels |

| • | Do not refill the DEF with Engine ON or ignition ON state |

| • | Ensure proper filling access for DEF filling during vehicle body building |

| • | When opening the DEF filler cap, ammonia vapors may escape. Refill DEF in a well ventilated area only. |

| • | Ensure that DEF does not come into contact with skin, eyes, or clothing |

Diesel Particulate Filter

(DPF)

During the regeneration process, take care the vehicle is not

near any flammable materials as you may observe hot emission

gases from exhaust pipe.

In order to avoid burns & personal injury, keep yourself

away from exhaust system.

Follow speed limits & traffic regulations as Defined by

local jurisdiction while doing forced regeneration

6 SEATS AND SEAT BELTS

6.1 Front Passenger Seat

To avoid personal injury, do not

operate or ride in vehicle until all occupants, including the driver, are seated properly

in the vehicle.

6.2 Driver Seat

6.2.1 Sitting in Correct Position

Follow the tips below for a comfortable and safe journey;

| • | Sit in an upright position with the base of your spine pressed against the seat back |

| • | The driver and front passenger seat head restraint has 5 positions. Adjust it as close as possible to the above specified position, with the top of the head restraint even with the top of your head |

| • | Maintain sufficient distance between yourself and the steering wheel. Maintain at least a ten inch (10") distance from the centre of the steering wheel to your chest |

| • | The top curve of the steering wheel should align with your chin for ideal road visibility |

| • | Adjust your seat and seat back angle such that your wrists rest on the steering wheel |

| • | Ensure your legs are in bent position while fully depressing the clutch pedal |

The seat should be adjusted while still maintaining control of the

foot pedals, steering wheel and your view of the instrument

panel controls.

Never adjust the driver's seat

while the vehicle is in motion. The seat may unexpectedly move and cause the driver to

unintentionally

operate the accelerator or brake, or turn the steering wheel, causing loss of control of the

vehicle, an accident or serious

personal injury. Adjust the driver's seat only when the vehicle is not in motion.

Never put objects under the

seats. They may interfere with the seat-lock mechanism or unexpectedly activate the seat

position

adjusting lever, causing the seat to suddenly move, resulting in loss of control of the vehicle,

an accident or serious personal

injury.

While adjusting the seat, do

not put your hands under the seat or near the moving parts. This may lead to injuries.

6.2.2 Front Seat Slide(if equipped)

Move the seat forward or backward by lifting the adjustment lever

located under the seat front and release once the desired

position is reached.

While adjusting the seat, make

sure the latch engages fully and the seat is locked firmly in the desired position. An unlocked

seat may move in a sudden stop or collision, causing injury to the person in that seat. Push and

pull on the seat to be sure

it is locked.

6.3 Head Restraint

6.3.1 Adjustable Head Restraint

The head restraint comprises of the padded portion which contacts your

head and is inserted/locked in receptacles on the top

of the seat back.

Your vehicle seats are equipped with head restraints which are

vertically adjustable. The purpose of these head restraints

is to help limit head motion in the event of rear collision.

Always align top of the head restraint with the top of your head or as

close to it as possible. To raise the head restraint,

press the lock knob and pull the restraint up. To lower the head restraint, press the lock knob and

push the head restraint

down.

6.3.2 Removing Seat Head Restraint

The head restraint can be pulled out completely by depressing the

locking button while pulling the restraint out.

6.3.3 Installing Seat Head Restraint

Align the head restraint shafts over the holes on the seat top and

push the restraint straight down till you hear the lock

click.

Keep the seat back as upright as possible so the headrest is behind,

not beneath, and almost touching your head.

Never drive with the head

restraints not properly adjusted, head restraints removed or inserted in a flipped condition.

With

no support behind your head, your neck could be seriously injured in a collision.

Head restraints are provided

for the front row and second row outboard occupants.

6.4 Folding of Seats

The second row seats cannot be folded.

The third row side facing seats can be folded as below;

| • | Lift and fold the seat |

| • | Swing the seat cushion fully up |

| • | Fold the seat leg completely down |

| • | Secure the seat by running the Velcro strap through the hook provided on the back of the seat cushion and sticking the Velcro |

To avoid serious injury, do not

sit on or place anything on a folded seat back while the vehicle is moving.

6.5 General Warnings and Instructions-

Seat Belts

At least once each month, inspect the seat belt webbing for any cuts,

tears, or other signs of wear (such as fraying along

the edges). Also inspect the anchors, retractors, and buckles to be sure they are tight and operational.

| • | All occupants, including the driver, should always wear their seat belt no matter how short the trip in order to minimize the risk of severe injury in the event of a crash. In an accident, an un-belted passenger becomes a projectile, and can cause serious injury to himself or another passenger. |

| • | In a rollover crash, an un-belted person is significantly more likely prone to Injury than a person wearing a seat belt |

| • | In order to be properly buckled, you must always sit up straight and keep your feet on the floor in front of you. The lap part must be worn low and tight across your hips, just touching the top of your thighs. While fastening the seat belt, the shoulder strap of the seat belt must pass over your chest and top of your shoulder. It must never touch your neck, face, the side of your shoulder, arm, or pass under your arm. The belt must always be flat against your body and not twisted in any way. Nothing, such as an arm rest, a pocketbook, or any external objects should be between you and the seat belt. Improper wearing of a seat belt will reduce the protection in an accident. |

| • | Seat belts should be adjusted as tightly as possible,

consistent with comfort to properly secure the wearer in the seat.

|

| • | The seat belts provided for your vehicle are designed for people of adult size, must be properly used and maintained. |

| • | For usage of adult seat belt to secure children refer to

section on manual for child seat positions and use a child restraint

systems

|

| • | Passengers should not move out of or change seats while the vehicle is moving. A passenger who is not wearing a seat belt can be thrown against the inside of the vehicle, against other occupants, or out of the vehicle during a crash or emergency stop |

| • | Do not use any accessories on seat belts or modify in any way the seat belt system. Devices claiming to improve occupant comfort or reposition the seat belt can reduce the protection provided by the seat belt and increase the chance of serious injury in a crash |

| • | An accident or emergency stop, can damage your seat belt system, even if the accident is “minor”. Please have your Authorized Mahindra Dealer inspect the seat belt system after an accident |

| • | Please be aware that any unsecured item in your vehicle, such as your pet, unsecured child restraint system, a laptop or mobile phones, can become a projectile in the event of an accident or sudden stop, causing injuries to occupants in the vehicle |

Never use a damaged seat belt

system. A damaged seat belt will not provide protection in an accident, resulting in serious

injury.

| • | Seat belt systems can be prone to abuse. They are not indestructible. They must be handled with care to avoid damage |

| • | Keep the belts clean and dry. Belt retraction may become difficult if the belts and webbing are soiled. If they need cleaning, use a mild soap solution or lukewarm water. Never use bleach, dye, or abrasive cleaners. These chemicals will severely weaken the belts |

| • | Retractors in 3-point type seat belts retract the seat belts when not in use. The inertia lock and coil spring allow the belts to remain comfortable on users during normal driving. During accidents or abrupt stops, inertia locks restrict the sudden forward movement of the wearer |

Seat Belts - Patients

Persons with serious medical conditions should also wear a seat belt.

Consult your doctor for specific recommendations before

travel.

Seat Belts - Pregnant Women

Pregnant women must also wear seat belts. Consult your doctor for

specific recommendations.

The lap belt should be worn snugly and as low as possible over the hips.

The shoulder belt should be worn across your shoulder,

but never across the stomach area. When worn properly, the seat belt will protect both the mother and the

foetus in an accident

or emergency stop.

A pregnant woman should never wear

the seat belt across the stomach area. This could lead to serious injuries to the foetus

and/or the pregnant mother.

Never wear twisted seat belts.

Excessive forces will be transferred from the belt to the wearer, in a collision, resulting

in serious personal injury.

Each seat belt is meant for use by

one person only. Using one seat belt for more than one person at a time is dangerous. The

seat belt will not be able to spread the impact forces properly leading to serious injuries.

Never put a belt around a child

being carried on the occupant's lap. This could lead to serious injuries.

Seat Belt Usage is Necessary

to:

| • | Reduce the possibility of being thrown from your vehicle |

| • | Reduce the possibility of injuries to upper body, lower body and legs during an accident |

| • | Hold the driver in a position which allows better control of the vehicle |

Children who are too large for child restraint systems should always

occupy the rear seat and use the vehicle seat belts.

The lap portion should be fastened snug on the hips and as low as possible and the shoulder strap should

be across the child's

shoulder, not the neck or face. If you are unable to position the strap across the child's shoulder, the

child should remain

in a booster seat. Frequently check the seat belt to be sure it remains snug and in position. A squirming

child could cause

the seat belt to come out of position.

6.6 Child Restraint System (CRS) (if

equipped)

Legend:

U — Suitable position for using

universal child restraint system using seat belt and buckles marked with ‘ C R S ’.

Ø — Not Suitable position for using

child restraint system using seat belt.

Always secure a child in a proper Child Restraints System in accordance

with age and size of the child as recommended by the

child restraint system manufacturer. Be sure to follow the Child Restraint System (Child seat)

manufacturer’s instructions

for seat belt routing.

Do not allow children to stand up

or kneel on either the rear or the front seats. An unrestrained child could suffer serious

injuries during emergency braking or collision.

The seat belt buckle marked with CRS comply with the requirements of

AIS72 for use with a child seat. The Child Restraint

system can only be used with the seating positions with buckle heads marked “CRS”.

| Mass Group | Weight of Child (kg) | Fitting the child restraints system using seat belt |

| Group 0 | 0–10 | Rear-facing child restraint system on the outboard 2nd row seats using seat belt. |

| Group 0+ | upto 13 | |

| Group 1 | 9–18 | Forward-facing child restraint system on the outboard 2nd row seat using seat belt. |

| Group 2 | 15–25 | |

| Group 3 | 22–36 |

6.7 Passenger Occupant Detection System

(PODS) (If equipped)

PODS system is to detect the presence of occupant in the seat.

Primary Warning: Seat belt LED

indication shall come ON in ignition ON condition if any of the driver / co-driver seat belt in unbuckled

with

occupant.

Seat belt buzzer audible warning will come ON for 30 sec once, if any of

the driver / co-driver seat belt is in unbuckled

condition or buckled to unbuckled with occupant at vehicle speed is above 10 kmph.

Over speed warning has highest priority compare to seat belt alert and

RPAS alert. Which means if vehicle speed crosses above

80 kmph then only high speed audible warning will be given although driver/co-driver seat belt with

occupant is not fastened.

7 SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

7.1 Airbags

Your vehicle is equipped with the following airbags:

| • | A frontal airbag for the driver |

| • | A frontal airbag for the front passenger. |

Airbags are located in:

| • | The steering wheel hub

|

| • | The passenger side instrument panel

|

They are indicated by “AIRBAG” embossed on the covers.

An airbag is not designed to

deploy in every type of crash. Depending on the type of accident or impact, the front airbags

independently deploy thereby protecting the occupants. It is not necessary that ALL the airbags

deploy during an accident.

To minimize the risk of severe injury in the event of a crash, every

passenger must always wear their seat belt (see the chapter

on Seat Belts in this manual). The airbags inflate very quickly with great force. Do not position any

part of your body too

close to a airbag, you or especially children could be seriously injured/killed by a deploying airbag.

7.2 Introduction

The airbags are designed to provide further protection to the vehicle

occupants in addition to the primary protection provided

by the seat belts.

The primary components of the system are the sensors which measure the

crash severity. In the event of a significant frontal

impact, the airbags inflate to work in conjunction with the seat belts and help reduce injuries mainly to

the driver's or

front passenger’s head/chest.

Seat belts are the primary

restraint system in the vehicle. An airbag provides supplemental protection in addition to the

seat belts.

All occupants, including the

driver, should always wear their seat belts irrespective of presence of airbags to minimize the

risk of severe injury in the event of a crash.

Airbags are more effective in

reducing injuries when the seat belts are worn.

7.2.1 Driver and Front Passenger Air

Bag

Your vehicle is equipped with a Airbag and lap/shoulder belts at both

the driver and front passenger seating positions. The

indications of the system's presence are the letters “AIR BAG” embossed on the airbag pad cover in the

steering wheel and

the passenger's side front panel pad above the glove box.

The SRS is designed to deploy the front airbags only when an impact is

sufficiently severe and when the impact angle is less

than ± 30° from the forward longitudinal axis of the vehicle.

Front airbag is not intended to deploy in side-impact, rear impact or

rollover crashes. In addition, front airbag will not

deploy in frontal crashes which are below the prescribed deployment threshold where risk of serious

injuries is low.

Do not place any objects over

the airbag or between the airbag and yourself.

7.2.2 Airbag System Malfunction Lamp

Airbags do not require any regular maintenance of service. The airbag

system malfunction lamp illuminates when the ignition

is ON as self check confirming normal operations of airbag system and malfunction lamp.

This lamp indicates malfunction of, any of the Airbag ECU assembly,

airbag sensors, indicator lamp, Seat belt assemblies,

Airbag inflators, interconnecting wiring and power sources.

If either of the following conditions occur, there is a malfunction of

any of the Restraint system. Immediately contact your

Mahindra Dealer.

| • | The lamp does not glow when the ignition is switched ON or glows beyond six (6) seconds after switching the ignition ON |

| • | The lamp comes ON at any other time, even briefly |

| • | The lamp comes ON intermittently |

Never make any modifications to

your vehicle which could affect the performance of your airbag system. In particular, changes

to the vehicle frame, bumpers, bull bar, front fenders, ride height, suspension, seat belts,

interior trim, seats or steering

wheel (especially covers, pads or other trim), could prevent proper deployment of the airbag. If

you need to make any modifications

to accommodate any disability you may have, please contact your Authorized Mahindra

Dealer.

Never try to open or strike the

airbag cover. If the airbag cover is cracked or damaged in any way, the airbag may not function

as intended. Take the vehicle to an Authorized Mahindra Dealer.

Even if the airbags do not deploy during an accident, take your

vehicle to an authorized Mahindra Dealer for a thorough inspection

of the airbag and seat belt systems, no matter how minor the accident. The airbag system could have

been damaged, and may

not work as intended in the future, resulting in serious injury.

7.2.3 Airbag Inflation/Deployment

The airbag sensors constantly monitor the forward deceleration of the

vehicle. If an impact results in a forward deceleration

beyond the designed threshold level, the system triggers the airbag inflators. This initiates a

chemical reaction which quickly

fills the airbags with non-toxic gas.

Upon deployment, tear seams molded directly into the pad covers

separate under pressure from the expansion of the airbags.

Further opening of the covers allows full inflation of the airbags. A fully inflated airbag, in

combination with a properly

worn seat belt, slows the driver's forward motion, reducing the risk of head and chest injury.

After complete inflation, the airbag immediately starts deflating,

enabling the driver to maintain forward visibility and

the ability to maneuver or operate other controls.

Deployment of the airbags happen in a fraction of a second, producing

a loud noise releasing a ‘white smoke’ and residue along

with a non-toxic gas. This does not indicate a fire. This smoke may remain inside the vehicle for some

time, and may cause

some minor irritation to the eyes, skin or breathing. Be sure to wash off any residue with soap and

water as soon as possible

to prevent any potential skin irritation. If you can safely exit the vehicle, you should do so

immediately.

| • | Do not modify, remove, strike or open the seat belt assemblies, airbag sensor or surrounding area or wiring. Failure to follow these instructions may prevent them from activating correctly, cause sudden operation of the system or disable the system, which could result in serious injury |

| • | Parts of the airbag module (steering wheel hub, airbag cover and inflator) may be hot for several minutes after deployment. The airbags inflate only once |

| • | Do not cover the steering wheel, instrument panel, seats with any object (e.g. dash panel covers, seat covers) which may prevent the airbags from inflating properly |

| • | The airbags inflate with considerable force. While the system is designed to reduce serious injuries, primarily to the head and chest, it may also cause other, less severe injuries to the face, chest, arms and hands. These are usually in the nature of minor burns or abrasions and swelling, but the force of a deploying airbag can also cause more serious injuries, especially if an occupant's hands, arms, chest or head is in close proximity to the airbag module at the time of deployment. Sit straight and well back into the seat. Move your seat as far back as practical to allow room for airbag inflation, while still allowing you to properly operate/drive the vehicle |

The front passenger should

never sit on the edge of the seat, stand near the glove compartment, rest feet or other parts of

the body on the dashboard when the vehicle is moving.

The driver or front passenger who is too close to the steering

wheel or dashboard can be seriously injured during airbag deployment.

| • | The driver must sit as far back as possible from the steering wheel while still maintaining control of the vehicle |

| • | The front passenger must sit as far back as possible from the dashboard |

| • | Sitting improperly or out of position can cause occupants to be shifted too close to a deploying airbag, strike the interior structure or be thrown from the vehicle resulting in serious injury |

| • | Always sit upright with the seat back in an upright position, on the seat cushion centre with your seat belt on, legs comfortably extended and your feet on the floor |

| • | All vehicle occupants must be properly restrained using the seat belts |

| • | All infants and children must be placed in the rear seat of the vehicle in a child restraint seat and be properly restrained by seat belts |

| • | Front airbags can injure occupants improperly positioned in the front seats |

| • | Even with airbags, improperly belted and un-belted occupants can be severely injured when the airbag inflates. Always follow the precautions about seat belts, airbags and occupant safety contained in this manual |

| • | Do not modify the front seats. Modification of the front seats could interfere with the operation of the supplemental restraint system |

| • | Do not place items under the front seats. Placing items under the front seats could interfere with the operation of the supplemental restraint system sensing components and wiring harnesses |

7.2.4 Child Restraint and Airbag

|

|

|

Never use a rearward facing child restraint on a seat protected by an

active airbag in front of it, Death or Serious injury

to the child can occur

This is indicated also on stickers that are located on the front

passenger’s sun visor.

In addition, do not place a child in front-facing child restraints in

the front passenger’s seat either, If the front passenger

airbag inflates, it could cause serious or fatal injuries to the child.

Never hold an infant or child

on your lap. The infant or child could be seriously injured in the event of a crash. All infants

and children should be properly restrained in appropriate child safety seats or seat belts in

the rear seat.

Install the child restraint

system on the rear outboard seats, and securely lock the child restraint system in position with

the help of rear outboard seatbelt

Always Buckle Children (ABC) in

the back seat. It is the safest place for children of any age to ride.

7.2.5 Airbag Deployment

The images shown in this

section are for illustrative purpose only. They may not look like your model/variant or

vehicle.

Front Air bag’s

Front air bags are designed to inflate in a frontal collision

depending on the intensity, speed or angles of impact of the

front collision.

Airbag Non-deployment

Impacts below a pre-determined threshold level may not cause the

airbag’s to deploy in the following cases:

| • | Collision with

Utility Poles or Trees -

Air bags will not inflate if the vehicle collides with

objects such as utility poles or trees, where the point of impact is

concentrated to one area and the full force of the impact is not delivered to the

sensors.

|

| • | Under-ride

Situations -

Running under a truck's tail gate may not provide the

decelerations necessary for airbag deployment. Just before impact, drivers

often brake heavily. Such heavy braking lowers the front portion of the vehicle causing

it to “ride” under a vehicle with

a higher ground clearance. Air bags may not inflate in this “under-ride” situation

where deceleration forces that are detected

by sensors may be significantly reduced by such “under-ride” collisions.

Rear-end Collisions

-

Frontal air bags are not designed to inflate in rear

collisions, where occupants are moved backward away from the airbags

by the force of the impact. In this case, inflated air bags would not be able to

provide any additional benefit.

|

| • | Frontal Impact

-

Frontal impact beyond 30º range from head-on to the

vehicle.

|

| • | Pot Holes or

Stepped Surfaces -

Driving into a big pot-hole, stepped surface or hitting

the far side of a hole/incline will not inflate the airbag.

|

| • | Rollover

-

Air bags will not inflate in rollover accidents where

air bag deployment would not provide protection to the occupants.

|

| • | Frontal Side

Swipe Impact -

Frontal offset impact to the vehicle may not provide

the deceleration force necessary for airbag deployment. In an angled

collision, the force of impact may direct the occupants in a direction where the air

bags would not be able to provide any

additional benefit, and thus the sensors may not deploy any air bags.

|

7.2.6 Airbag Replacement

Self-servicing or tampering with the airbag system is dangerous. An

airbag could accidentally deploy causing serious injuries,

or will not deploy when there is a need. Always take your vehicle to an authorized Mahindra dealer for

inspection and repairs.

7.2.7 Self Removing SRS Related

Parts

Self removing the instrument panel, steering wheel, seats or airbag

related parts or sensors is not recommended. Airbags could

accidentally activate and cause serious injuries, or they may not deploy when there is a need. Visit

an authorized Mahindra

dealer if these parts must be removed.

7.2.8 Airbag Disposal

Improper disposal of an airbag or a vehicle with live airbags can be

extremely dangerous. Approach an authorized Mahindra

dealer to do these jobs.

8 LOCKS AND KEYS

8.1 LOCKS AND KEYS

A Word About Your Keys :

Bolero comes with two types of keys based on the model/variant;

| • | Conventional |

| • | Remote Keyless Entry (RKE) |

Conventional Keys

Two conventional keys are given along with your vehicle. You can insert

the key into the ignition with either side up.

Key Number

Tag :

Your key number is

shown on the plastic tag attached to the key. It is recommended that you record the key number and store

in a safe place.

The keys operate all

locks in your vehicle including those of the doors and ignition with steering lock. We advise you to

keep one of these keys at a safe place for emergency use, but not in the vehicle. Should you lose your

keys or if you need

replacement keys, they can be ordered through an Authorized Mahindra Dealer.

Never leave the key in the

ignition switch with children in the vehicle. A child could switch on the ignition, start the

engine,

operate power windows and other controls, or move the vehicle, resulting in personal injuries of

bystanders and/or children

seated inside.

Precautions while handling

keys:

| • | Do not cover the key grip with any material that cuts off electromagnetic waves |

| • | Do not leave the key exposed to high temperatures for a long period, such as on the dashboard or hood under direct sunlight |

| • | Do not put the key in any liquid or wash it in an ultrasonic washer |

To Open a Door from Inside:

To open the door from inside, pull the door lever away from door and push

the door out to open.

To Open a Door from Outside :

To open the door from outside, lift the door handle to unlock the door

and firmly pull to swing the door open.

Locking/Unlocking Doors from inside:

| A | UnLock | B | Lock |

Individual doors can be locked/unlocked from inside by using door lock

tabs. Lift the tab (B) to lock and press the tab (A)

to unlock.

Locking/Unlocking Doors from Outside

:

The driver door and the rear tail gate can be locked/unlocked from

outside using the key.

A key hole is provided in the

driver door and front passenger door, to lock/unlock the doors manually from outside.

Locking/Unlocking the Back Door

:

The tail gate can be locked or unlocked using the conventional key from

outside. Turn the key clockwise for locking the tail

gate and anti-clockwise for unlocking the tail gate.

8.2 Central Locking

System (if equipped)

All doors of the vehicle can be locked and unlocked from the driver door

by the central locking system.

8.2.1 Central Locking/Unlocking All

Doors from Outside

To lock/unlock all the doors simultaneously from outside using the

conventional key, turn the key clockwise/counter clockwise

in the driver door.

8.2.2 Central Locking/Unlocking All

Doors from Inside

| A | Unlock | B | Lock |

To lock/unlock all the doors simultaneously from inside, press the

driver door lock tab inwards (A) to unlock or pull the

tab outwards to lock all doors simultaneously.

8.2.3 Child Safety Rear Door Lock

Your vehicle is equipped with left and right side child safety rear

door locks. When the lock mechanism is engaged, the rear

door(s) cannot be opened from the inside. The door(s) can only be opened from the outside.

To activate/deactivate the Child-Protector Right Rear Door Lock push

the lever down/up till you hear a distinct click indicating

the activation/deactivation of the child lock.

Mahindra strongly recommends

that the child safety rear door locks be used whenever there are children traveling in the rear

seat.

Ensure the child safety lock is

de-activated if the rear doors are not operable from inside. However the rear doors can be

opened from outside when the child safety locks are activated.

8.3 Remote Keyless Entry

(RKE) System(If Equipped)

A RKE along with a conventional key is given with your vehicle. The front

side of the RKE has three control buttons.

|

A

|

LED

|

|

B

|

Lock

|

|

C

|

Search (Panic Alarm)

|

|

D

|

Unlock

|

To open the key from the RKE unit, press the key Unlock button (D) on the

RKE. You can insert the key into the ignition with

either side up.

Changes or modifications made to

this system by anyone other than an authorized service facility could void authorization

to use this equipment.

While programming a new key set, you will have to submit all the keys

available with you, at an Authorized Mahindra Dealer.

Please note that there is a limitation (max 2 keys at a time) to the number of keys that can be ordered.